E-Waste 3D Printer

In my second year CAD course at OTU, we learned about different rapid-prototyping techniques that are used in concurrent engineering and design. Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM) was one of the rapid prototyping technologies that the course covered and I was eager to learn about. After the course ended, I wanted to learn more about how FDM printers function and the programming behind the design. Before I set out to buy my own FDM 3D printer, I decided to make one out of old optical disks to see if could manage to make a small model and in process achieve my learning goals.

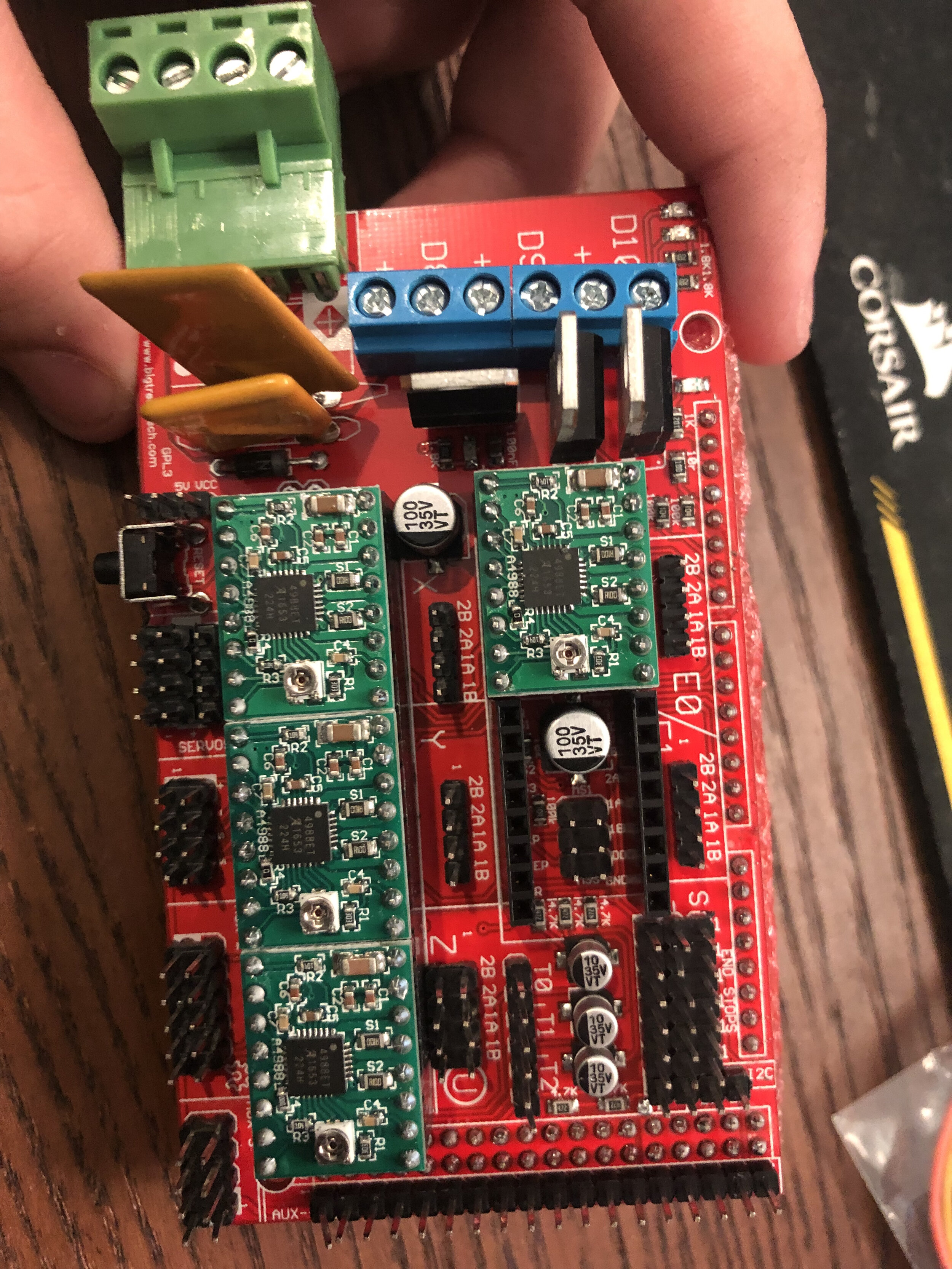

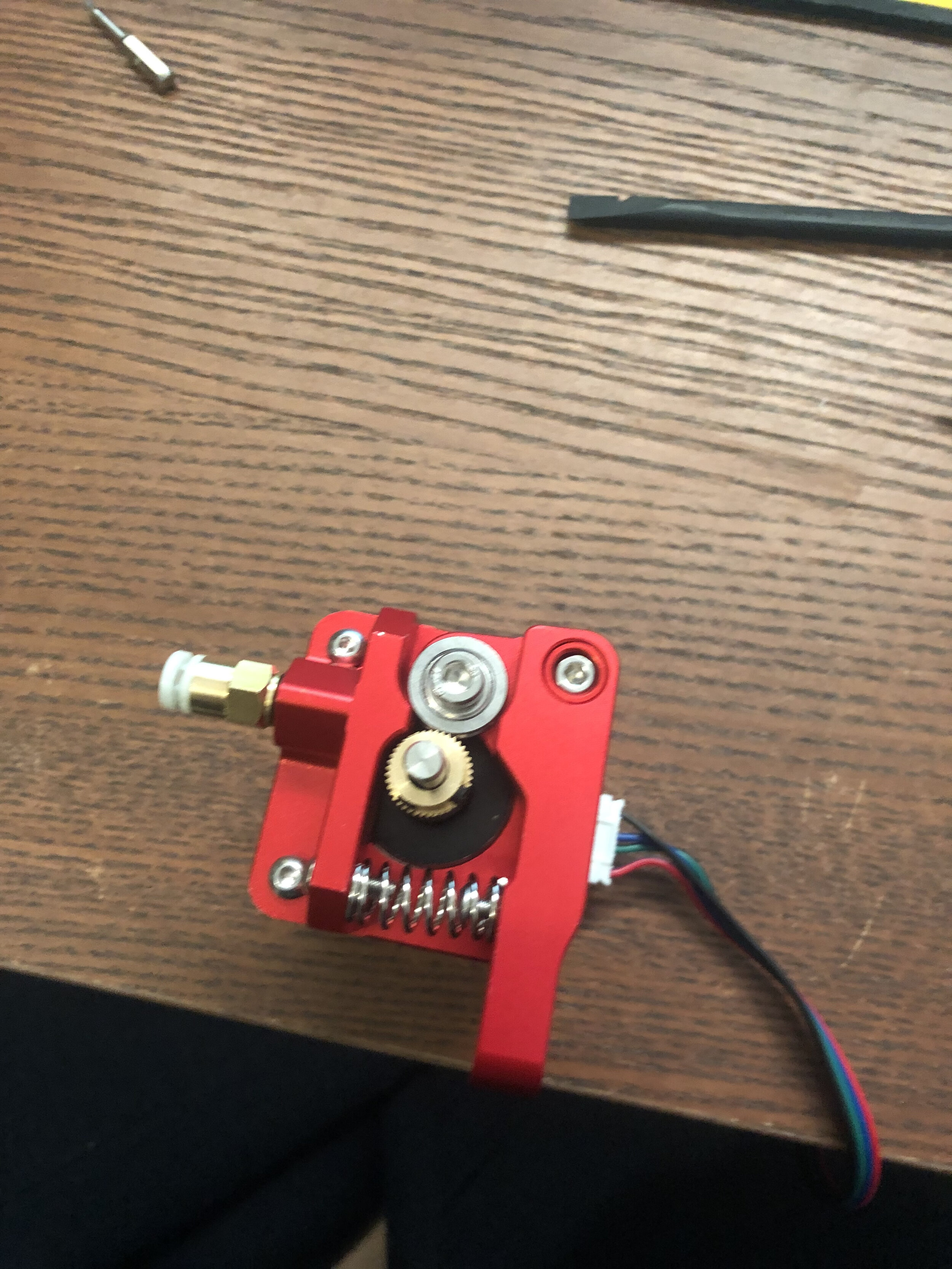

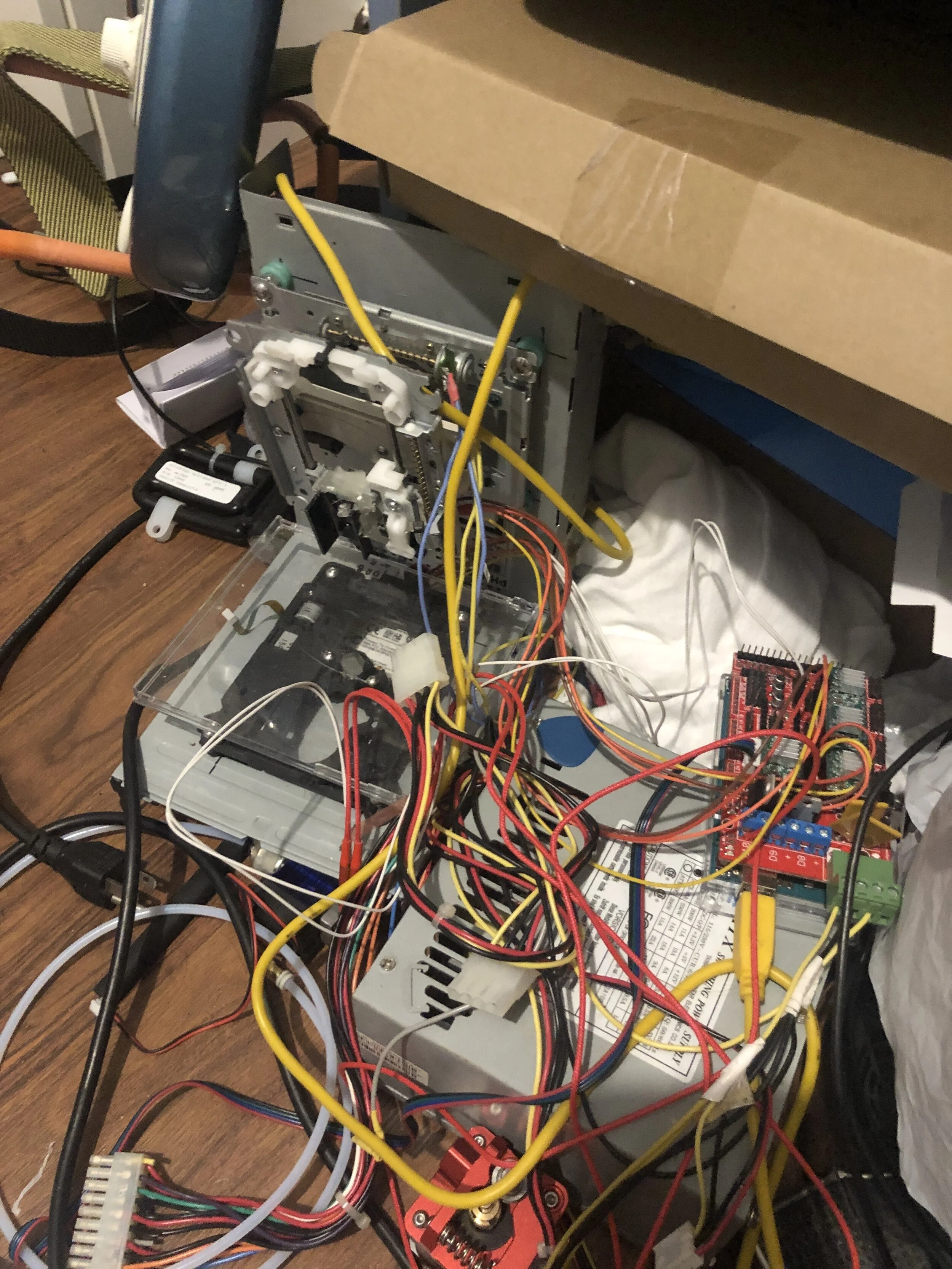

To accomplish this, I took three old optical disk drives apart and used their stepper motors to create what would be the X, Y, and Z axes. The stepper motors and their respective pins were connected to a RAMPS shield which was also attached to an Arduino Mega. I used Visual Studio Code to modify the open source firmware Marlin and uploaded this to the Arduino. At the end of the project, my carriage design was too heavy to hold the hotend of the 3D printer and would only be able to extrude melted filament. The project was a still a success due to how much I learned in the process.

In addition to being familiar with the marlin firmware (what I would later use when modifying my Ender 3), some key takeaways from the project included how a stepper motor works and the purpose of an H-bridge, how a Cartesian printer works in 3D space, how to utilize slicers to create GCode, how the components of the hotend are used to melt and keep the filament at a certain temperature, and the practical usage of tools (soldering, dupont crimpers, and a hand drill for holes).

Using VS code to modify the Marlin firmware