Robotic Snow Plow

This is a project that i’m still working on!

Objective of the Project

During the winter, my driveway at home receives a lot of snow. When the snow gets to a certain height, it makes more sense to use a snow blower. However, because snow storms and a large amount of snow don’t come as often to keep fresh fuel ready or keep the snow blower in an accessible spot, it becomes more of a hassle and waste of time to use it. After seeing some videos online of people making RC controlled robotic plows, I wanted to see if I could make one that was easy to use, run on batteries, and plow snow with minimal mechanical intervention from the user.

Current Progress

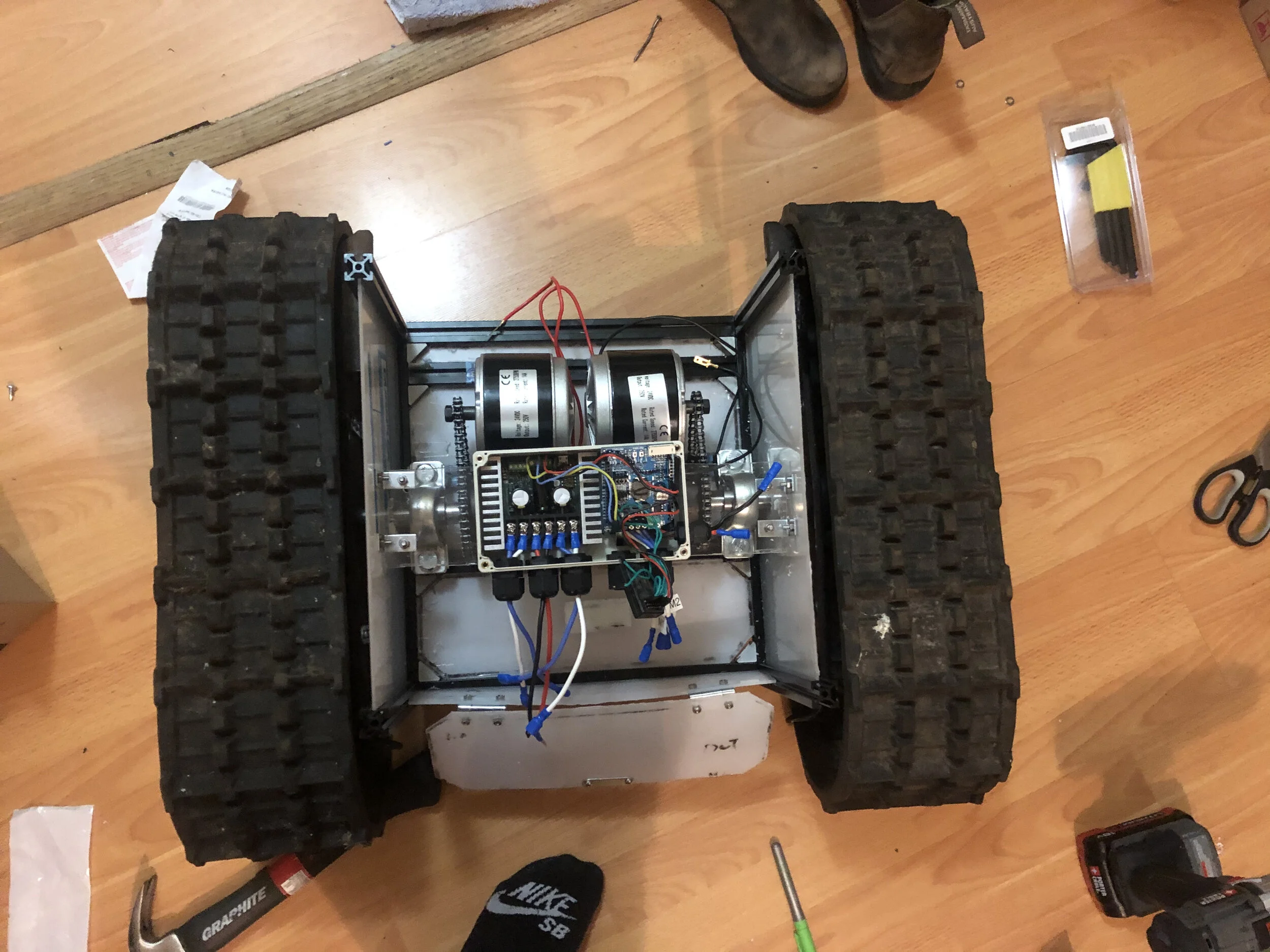

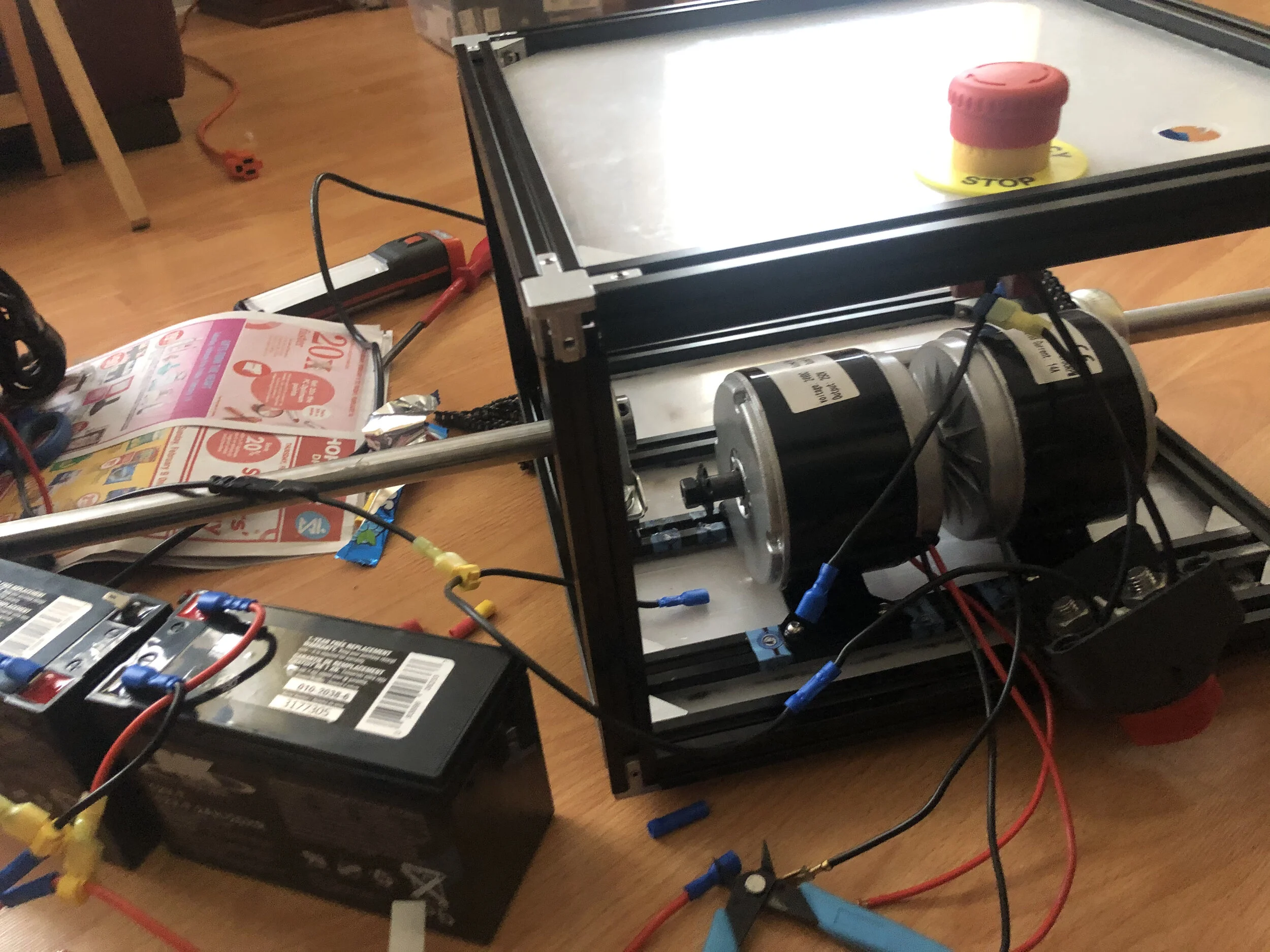

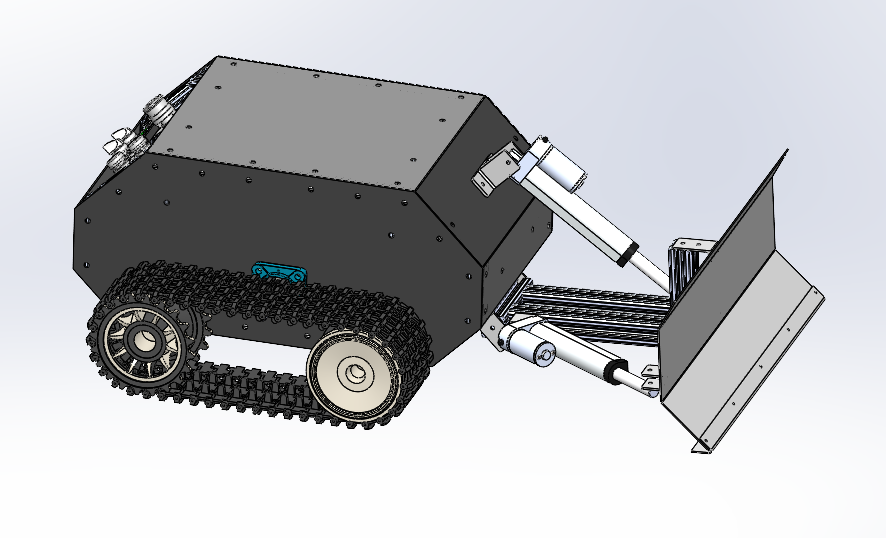

Currently, this has been the biggest project that I have taken on. Many of the obstacles I’ve come across are related to the chassis, drive train, and mechanical plow design. I’ve split the project into two main components, the main robotic base and the plow system. Currently, the main robotic base is almost complete. The new challenge i’m facing is how the torque is transmitted from the electric motors to the continuous track system. This is a Trac Drive system I bought from a seller off Kijiji. Unfortunately, majority of the parts in these tracks have rusted and seized making it a difficult challenge to get the base to move.

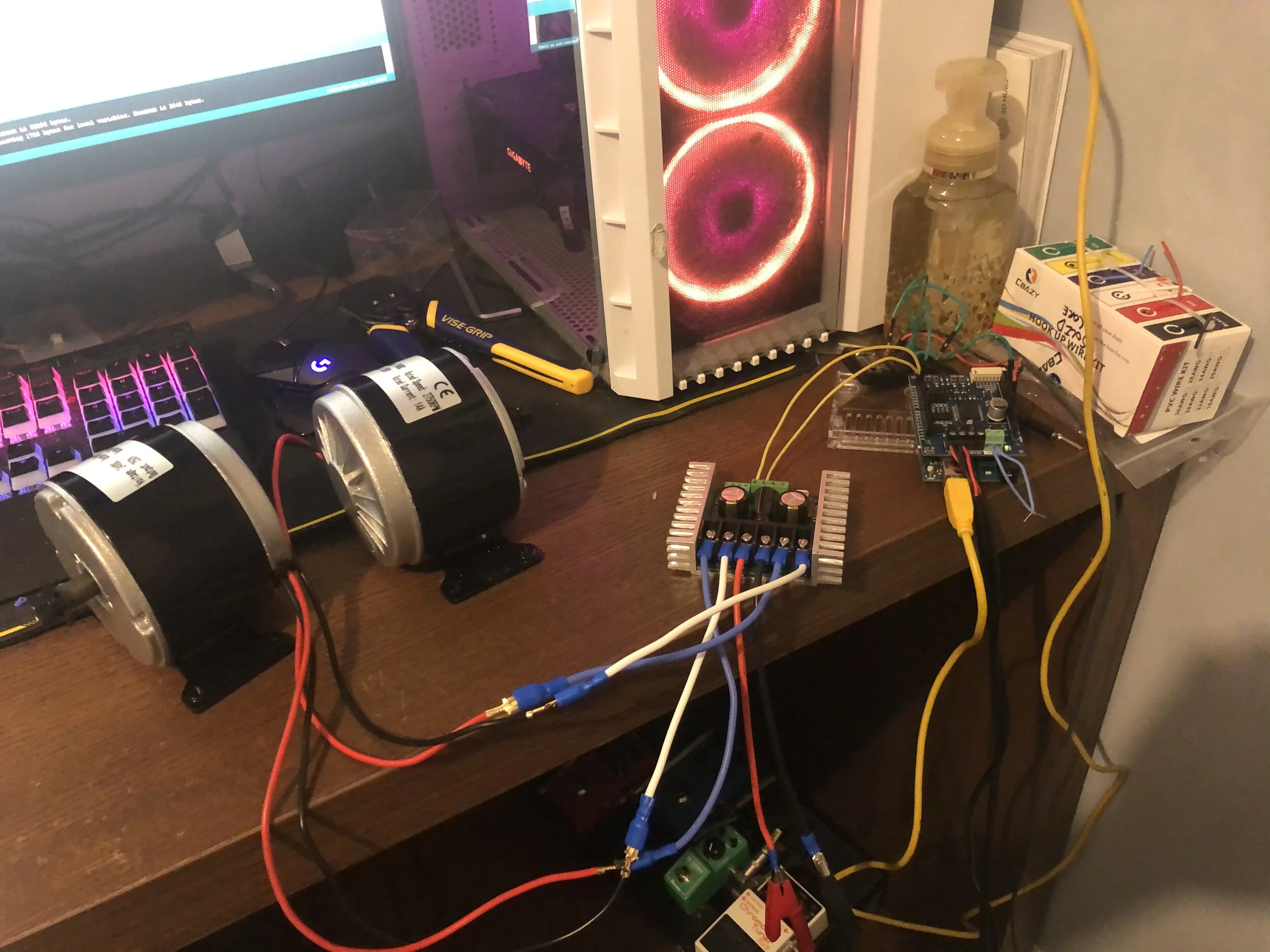

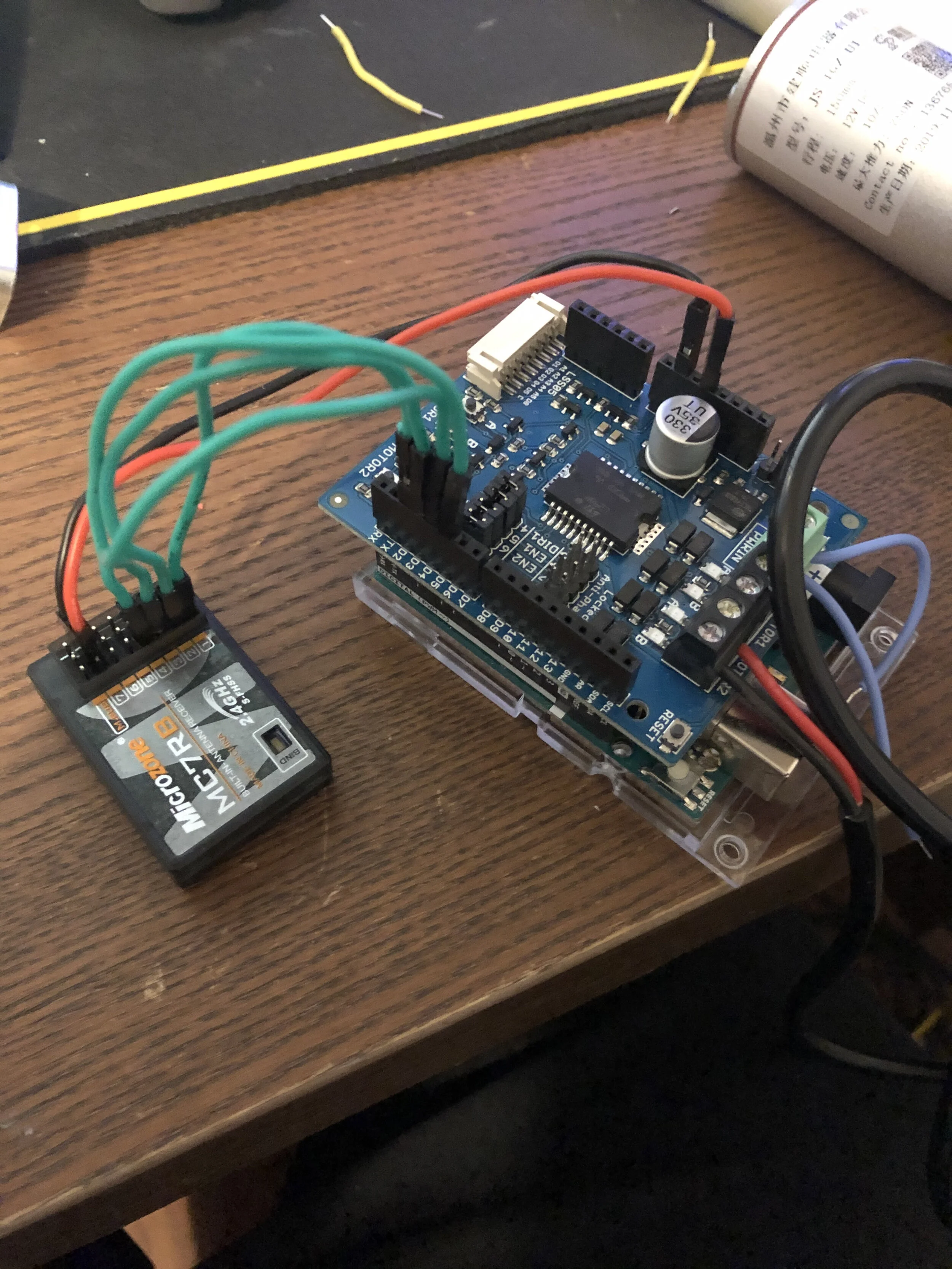

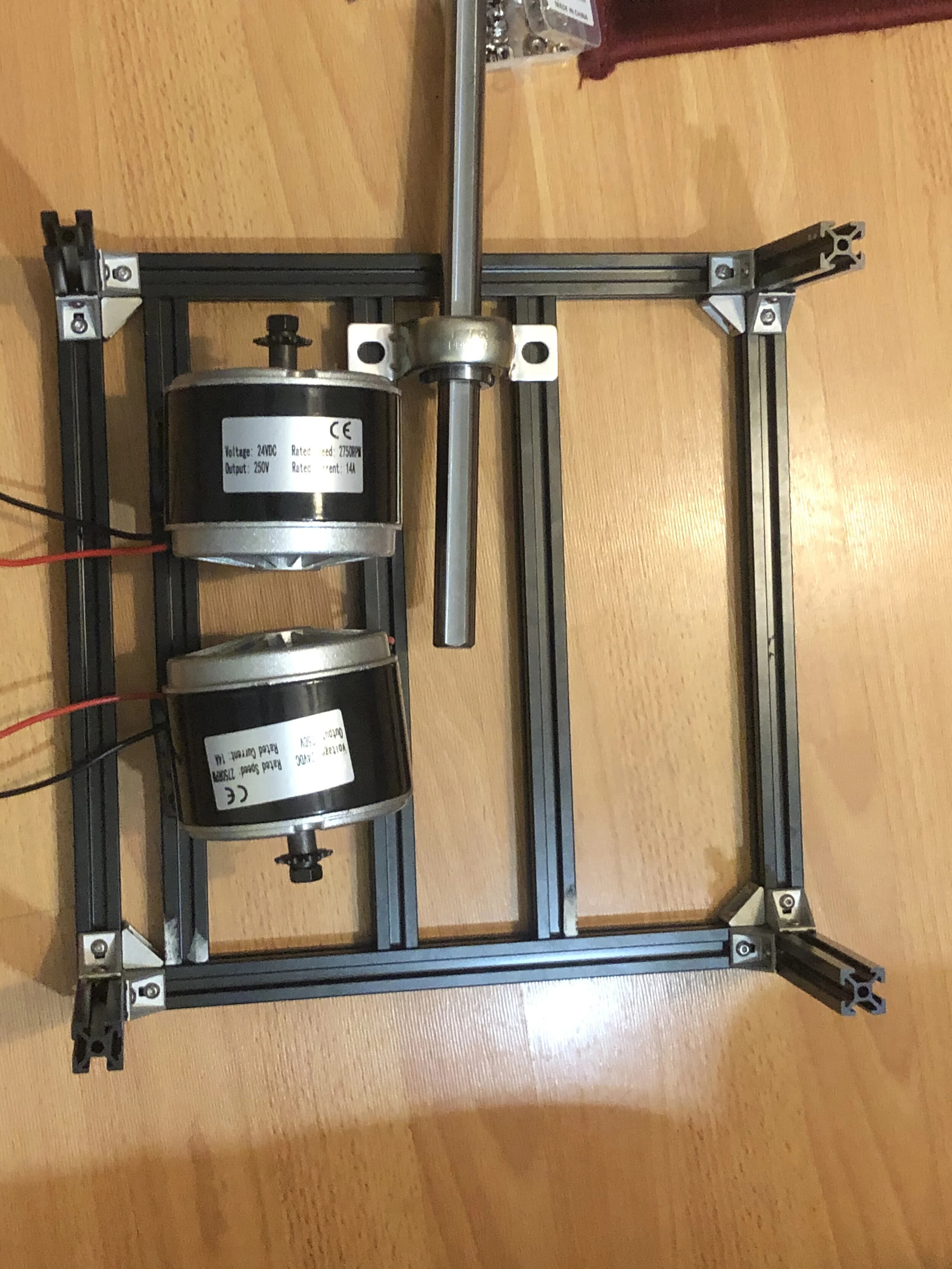

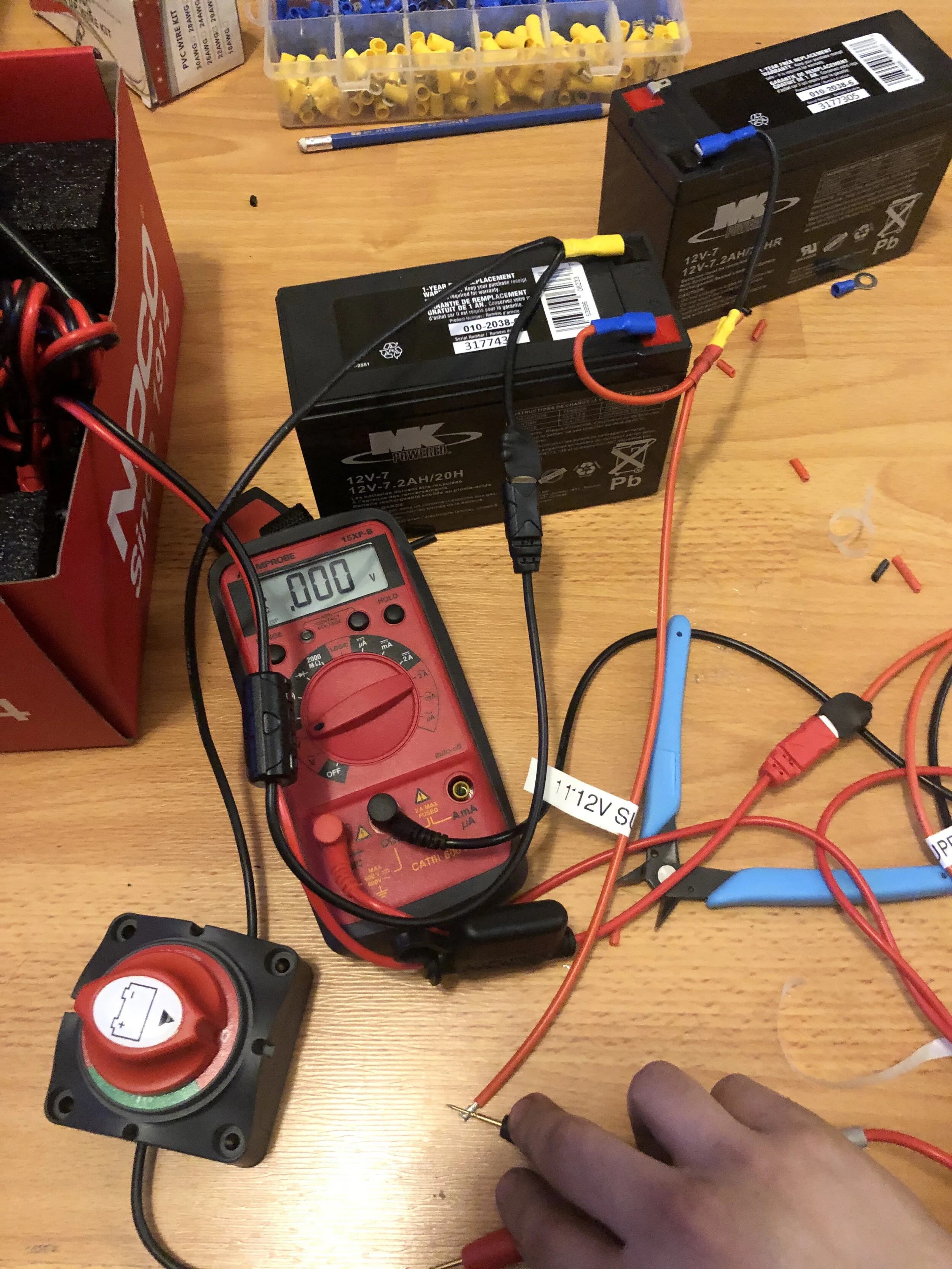

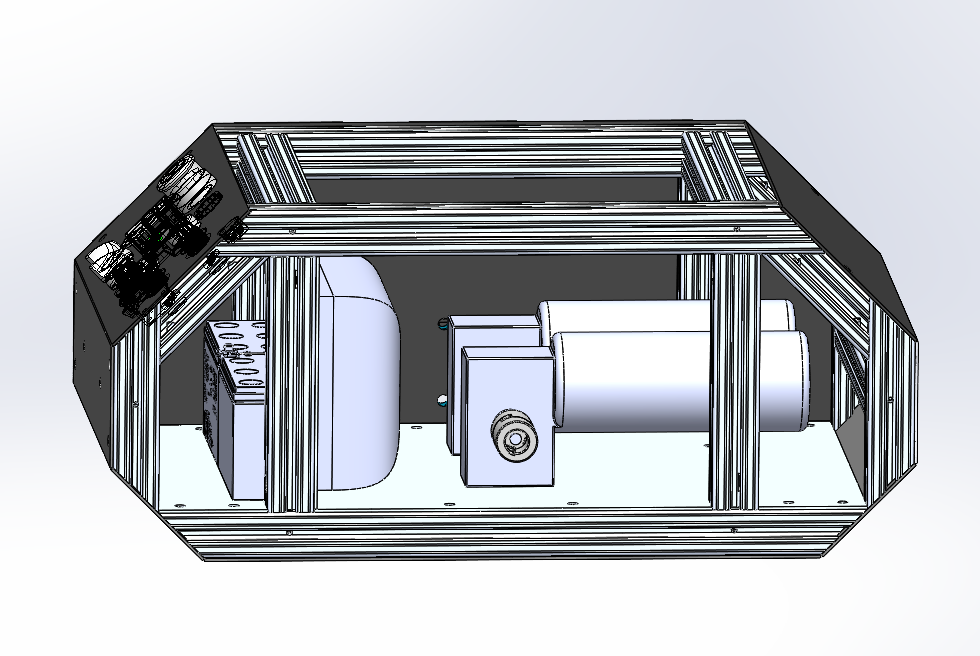

To control the movement of the robot and the plow system it self, I elected to use an Arduino microcontroller. The Arduino Uno has a motor shield attached to it. This motor shield will be used to control three 12V linear actuators which are a part of the plow system. A Sabertooth Dual 2x32A motor driver is used to drive two 24V electric motors, capable of 2750 RPM. I made a couple of test sketches that helped me figure out which channels are which on the RC controller that I chose. In the main program, I coded it such that the input frequencies from the RC controller are transmitted to the RC receiver module (the usual way the RC interface works).

However, the signals that are received from the RC receiver are connected to pins on the Arduino Uno as inputs. In the case of the Sabertooth circuit, this motor driver communicates to the Arduino Uno via serial. When it receives input from the appropriate channels, the Sabertooth drives the two motors in arcade drive. Due to the L298P chip being an Arduino shield, no extra preparation is required and can be utilized in the sketch with its appropriate functions.

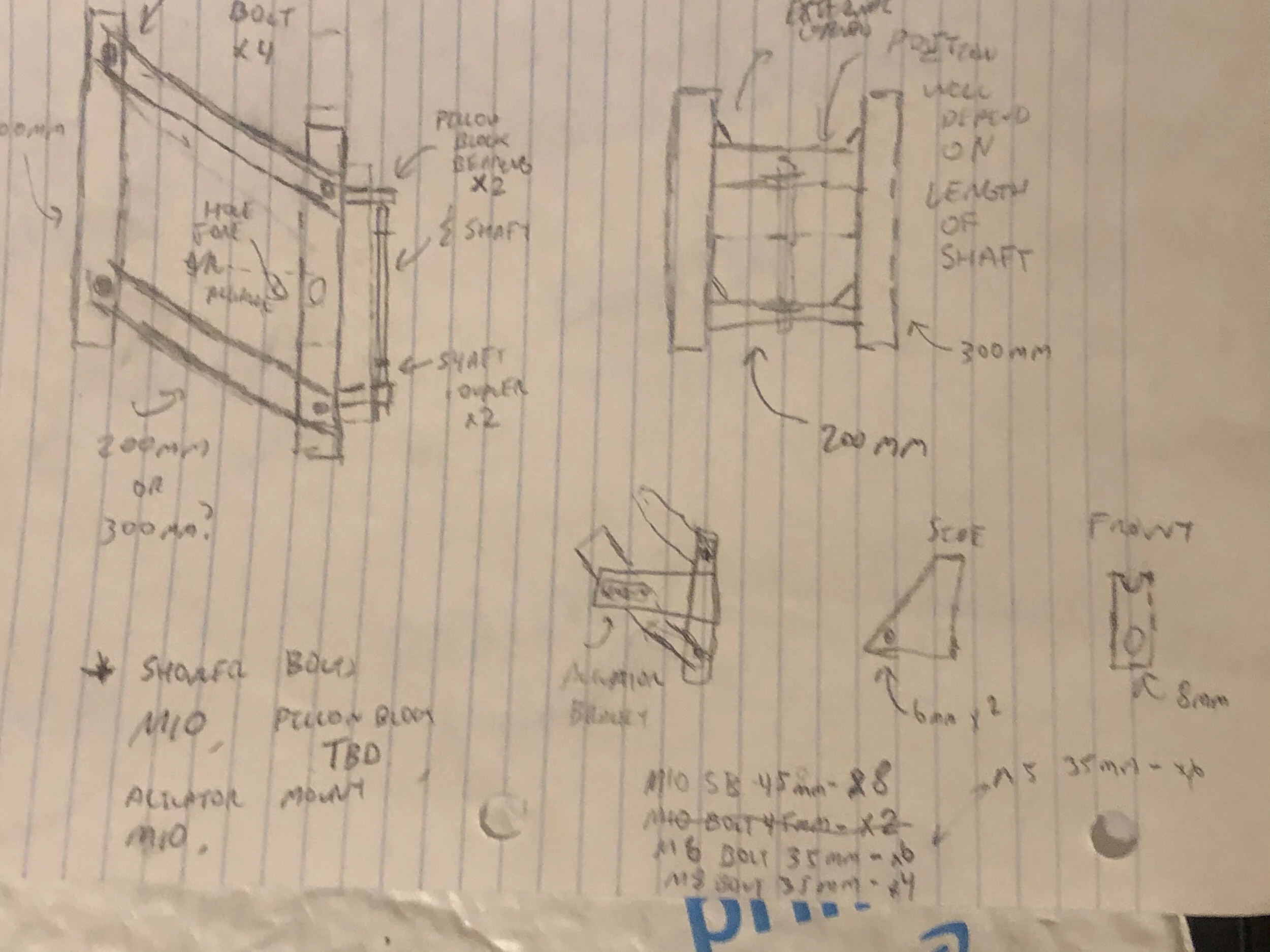

For the plow system, I decided to use aluminum extrusions to create a kinematic linkage. This will be responsible to lift and lower the snow blade. The main design challenges to consider were how to keep the linkage of the snow blade rigid so that it would be able to handle the opposing force created by the snow and how to rotate the snow blade. In the preliminary designs I found that keeping the linkage rigid and attached to the body often meant that the snow blade would be constrained from rotation in the Z-plane. In some robotic plow designs I researched, this often was the case.

However, I really wanted to incorporate this feature as it would ease the load encountered on the snow blade if it was rotated to one side. Additionally, this would make it easier to move the snow in different directions without the need to stop the robot and change its direction to match the intended movement of the snow. The final design uses pillow bearings and an aluminum shaft to allow the snow blade to rotate. The rotation of the snow blade is done by manipulating two linear actuators to push or pull the snow blade while the third linear actuator does the same to raise or lower the linkage.

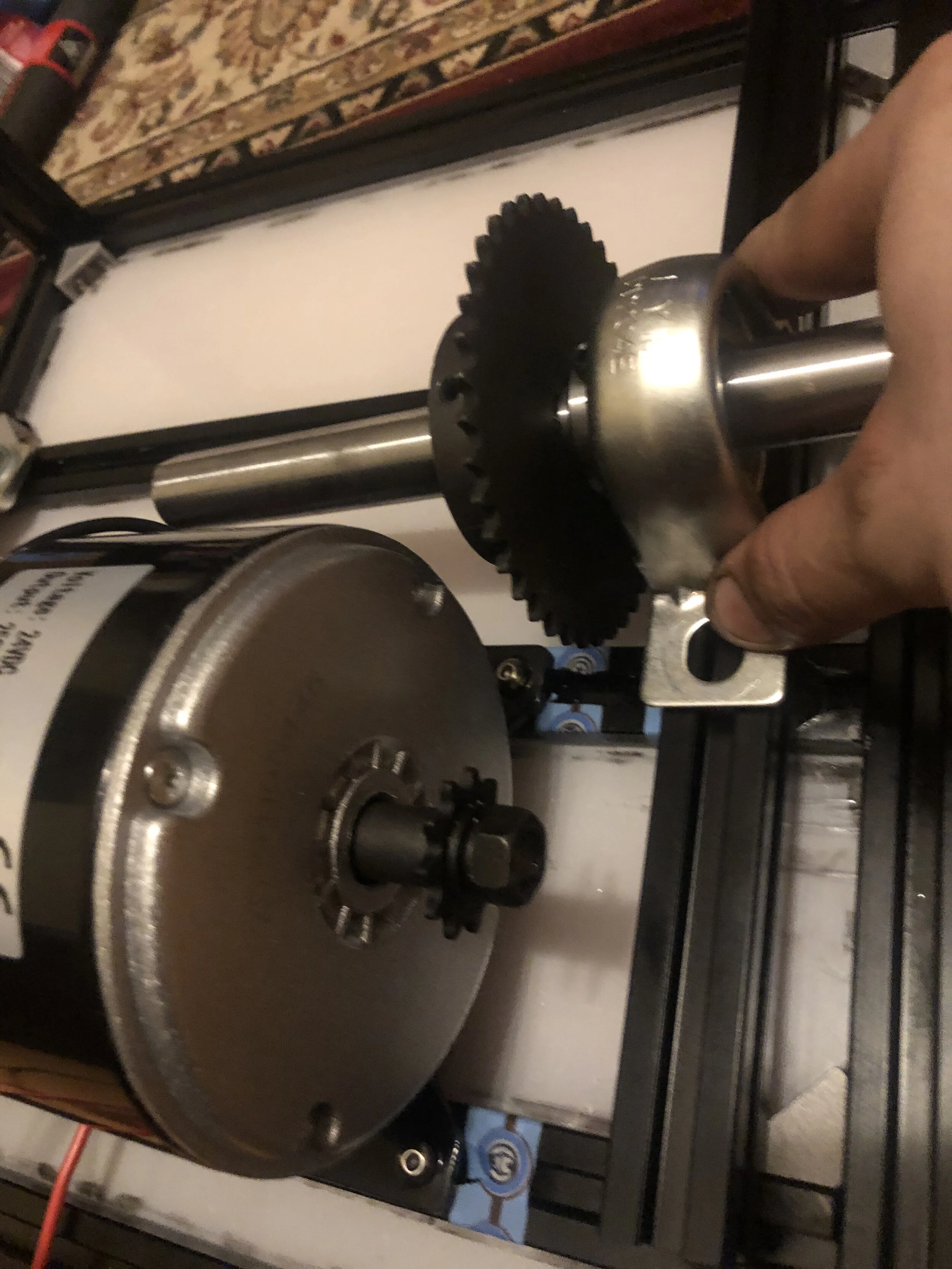

The current challenge that I’m working on solving is the Trac Drive system. Due to corrosion, many of the parts responsible to move the continuous track have seized. The Trac Drive system moves the continuous track by a sprocket and chain system. In the above picture, the sprocket is attached to the shaft by a pin (this keeps it from translating linearly and rotating along the shaft). When the shaft experiences an input torque, this turns the sprocket which then transmits this torque using a #41 chain that is attached to a larger plastic hub (this can be seen in the fourth picture below). This plastic hub has extrusions on the side that fit on top of the continuous track to allow it to move.

At first, I thought my only challenge was removing the seized shaft from the sprocket and replace it with a similar but longer rod. The sprocket would then be tapped and attached to the new shaft using a set screw. However, after attaching the new shaft to the Trac Drive sprocket, the continuous track had trouble moving. Due to exams and my school workload, I have paused on working on this project until I can find time to work on it. My current suspicion is that the chain in the Trac Drive system is too stiff to rotate the hub but another possible suspicion is that the load on the shaft is too large for the electric motor and it’s rated torque output.

2021 Progress Update

Throughout the year, I spent time redesigning and working on chassis design along with a very quick rough assembly of the snow blade actuation.

Motors from the previous build were also replaced with motors from an old electric-powered wheelchair on Kijiji. These new motors have a shaft to attach couplers to and run on 24V. After taking the magnetic breaks out of the motors, they were quickly wired up to the Arduino to test the tank-style driving with an RC controller.

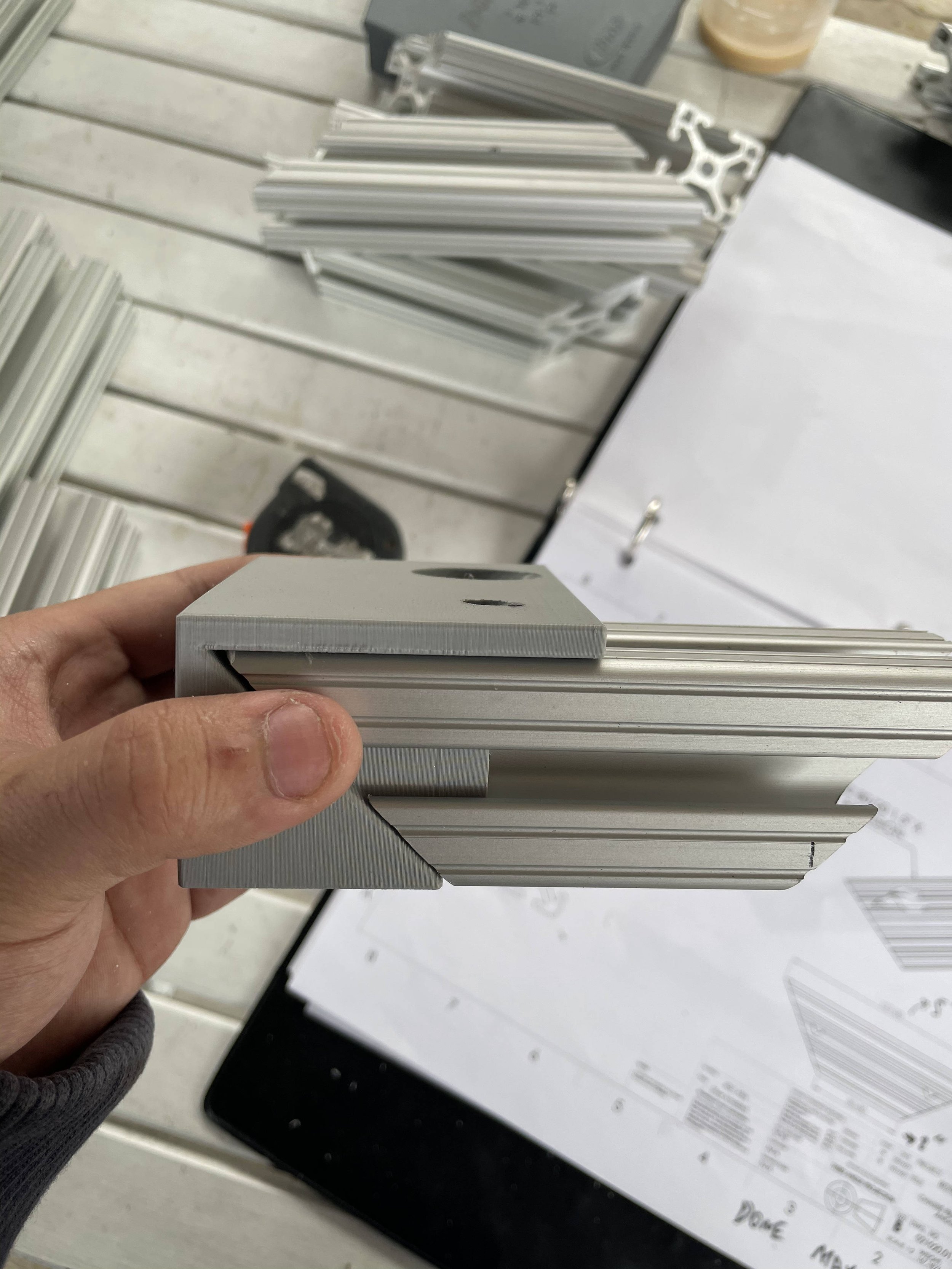

To help keep track of cuts neeed to be made for the aluminum extrusion, assembly and part drawings were made. 3D printed jigs were also used to help drill 45 degree counterbores and clearence holes.

This is how the frame of the chassis looks after assembling the extrusions together. Unfortunately, the redesign of this project was being done while I was completing my 12 month internship, thus alot of the planned modifications have not been implemented yet but there are still more updates to come!